The South Bend 431 “Masterpiece”

This watch was sent to me by a friend to do a simple Clean, Oil and Adjustment (COA). It is the top line 12s South Bend and one of the nicest 12s watches ever made. It is far superior to the “Mail Order” Studebaker 21 jewel by at least a factor of three. At the time this watch was made each of the major companies (Elgin, Waltham, Gruen, Hamilton, Illinois, etc.) made a “flagship” model to prove their watchmaking prowess. As a natural corollary I believe these watches were not really made to sell so much as to promote. They were advertised for sale for over eight years. The 431 only had a total production of 3 runs of one thousand, making it one of the rarest and most desireable of the South Bend 12s production series for serious collectors. The 431 only came in a “Permanent”, 14k or 18k case, thus elevating the price considerably and ensuring that only the deepest pockets could afford one. All of the pictures in this “pictorial” are of the watch after cleaning and during reassembly.

Spectacularly all of the steel parts on the dial side, including the keyless works, have been shined to a mirror finish. This is not only “mere” showmanship but is a statement. Even the end of the set lever screw has been shined to a mirror finish. You would be hard pressed to find a watch of any era that showed this attention to detail.

The mainplate has a very nice “pearlage” application that is not regularly seen on the dial side of a watch movement.

Just a pretty picture of the minute wheel and keyless works gears.

I have never seen a minute wheel done so nicely.

The movement side of the mainplate. All I can say is “WOW”! The entire plate is decorated, and decorated with loving care. It is very hard to do the pearlage inside the milled recesses for the 3rd and 4th wheel and this extra attention sets the mainplate apart from most other watches of the period. Also, it is very unusual to find decoration in the recess for the mainspring barrel.

The movement side of the mainplate. All I can say is “WOW”! The entire plate is decorated, and decorated with loving care. It is very hard to do the pearlage inside the milled recesses for the 3rd and 4th wheel and this extra attention sets the mainplate apart from most other watches of the period. Also, it is very unusual to find decoration in the recess for the mainspring barrel.

The plates. As can be seen this is number 619610, the 610th grade 431 out of a total production of three thousand. The serial number dates this movement to 1910. It is from the 1st run of 431’s and the 2nd run of all South Bend Chesterfield 12 size watches made of which there were 135 total runs. Out of an approximate 140k Chestfields this was the 1610thproduced.

The plates. As can be seen this is number 619610, the 610th grade 431 out of a total production of three thousand. The serial number dates this movement to 1910. It is from the 1st run of 431’s and the 2nd run of all South Bend Chesterfield 12 size watches made of which there were 135 total runs. Out of an approximate 140k Chestfields this was the 1610thproduced.

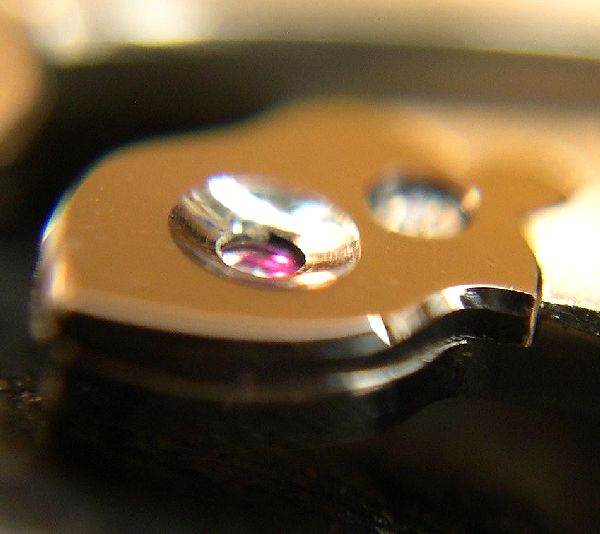

Beautiful 10k Gold Jewel settings. On many of the lower grade watches the jewels will be white or clear, indicating usually that they are made of “garnet” which was a cheaper and less sturdy jewel. All of these are the nice sapphire red which indicates a high quality jewel. Also, when a “composite” setting is used, made of brass, the shine of the setting is not as nice.

Beautiful 10k Gold Jewel settings. On many of the lower grade watches the jewels will be white or clear, indicating usually that they are made of “garnet” which was a cheaper and less sturdy jewel. All of these are the nice sapphire red which indicates a high quality jewel. Also, when a “composite” setting is used, made of brass, the shine of the setting is not as nice.

After many tries this is the best picture I could get of the cap setting and jewel on the escape wheel. The important thing to note here is the 45o cut on the steel jewel setting. It is finished to an absolute mirror finish on a curved cut. Not an easy job at all.

After many tries this is the best picture I could get of the cap setting and jewel on the escape wheel. The important thing to note here is the 45o cut on the steel jewel setting. It is finished to an absolute mirror finish on a curved cut. Not an easy job at all.

All of the undersides of the exposed plates are also finely finished. Just another detail that sets it apart from the ordinary. There actually is a slightly practical reason to finish the plates this way. Supposedly the pearlage finish is designed to trap dust, dirt and gunk that would otherwise go somewhere in the movement where it would cause wear and damage.

All of the undersides of the exposed plates are also finely finished. Just another detail that sets it apart from the ordinary. There actually is a slightly practical reason to finish the plates this way. Supposedly the pearlage finish is designed to trap dust, dirt and gunk that would otherwise go somewhere in the movement where it would cause wear and damage.

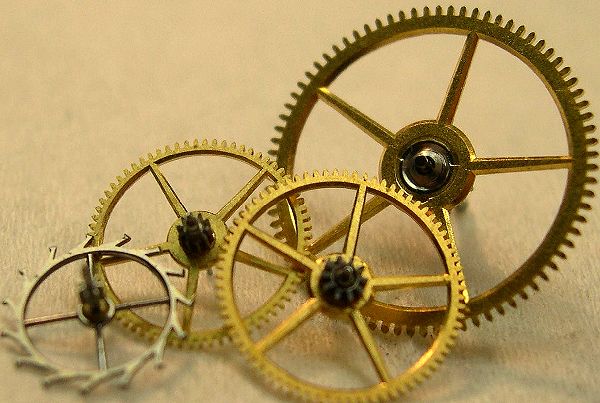

The gear train is gilded gold for the center, 3rd and 4th wheel, and a highly polished and refined steel for the escape wheel. All of the gold wheels have a 45o degree cut on each spoke. A very classy and performance enhancing detail.

The gear train is gilded gold for the center, 3rd and 4th wheel, and a highly polished and refined steel for the escape wheel. All of the gold wheels have a 45o degree cut on each spoke. A very classy and performance enhancing detail.

The escape wheel is a piece of art. The rounded spokes indicates that it was cast instead of stamped. On the edge of all 15 “teeth” there has been made a 45o cut that takes away approximately 80% of the surface area of the escape tooth end. This is a very delicate process but if done correctly leads directly to better watch performance. The bearing area where the escape wheel slides over the pallet jewel is reduced by 80%. This leads to much greater power and efficiency due to reduced “slide” friction. Sorry the pictures aren’t better.

The escape wheel is a piece of art. The rounded spokes indicates that it was cast instead of stamped. On the edge of all 15 “teeth” there has been made a 45o cut that takes away approximately 80% of the surface area of the escape tooth end. This is a very delicate process but if done correctly leads directly to better watch performance. The bearing area where the escape wheel slides over the pallet jewel is reduced by 80%. This leads to much greater power and efficiency due to reduced “slide” friction. Sorry the pictures aren’t better.

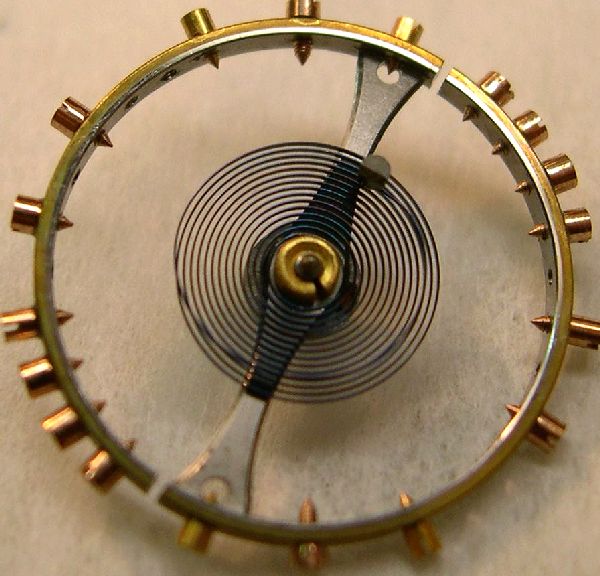

Not much to say about the balance except that all the balance screws are gold and the steel spokes are also finished with a 45o cut on both sides. A very delicate task and a detail that is almost unheard of in any make of watch. The Breguet Overcoil spring exhibits a classic and perfect shape with no apparent signs of rust. That is heartening because it obvious that this watch was well used and serviced many times prior to me getting my hands on it. Rust on the spring will lead to a weaker action and a need to reduce the weight on the balance, repoising, etc. Thankfully this balance is so well preserved it is just about the same as when it came off the production line 95 years ago.

Not much to say about the balance except that all the balance screws are gold and the steel spokes are also finished with a 45o cut on both sides. A very delicate task and a detail that is almost unheard of in any make of watch. The Breguet Overcoil spring exhibits a classic and perfect shape with no apparent signs of rust. That is heartening because it obvious that this watch was well used and serviced many times prior to me getting my hands on it. Rust on the spring will lead to a weaker action and a need to reduce the weight on the balance, repoising, etc. Thankfully this balance is so well preserved it is just about the same as when it came off the production line 95 years ago.

The “All Finished” shot. A very pretty and rarely seen movement. You can even see the bevelage on the whiplash regulator. On the timing machine it shows a maximum variation of 9 seconds between all positions and an amplitude of 280o in the dial up position. A good result for a watch of any age. The basic design for the Chesterfield series of movements was done by George Reed who also did several of the designs for the Rockford Watch Co. Personally I think this watch, the grade 431, ranks up in the top 10 of any 12s movement made. The fit, finish and detail matches or exceeds any watch of similar quality from that era that I have worked on.

The “All Finished” shot. A very pretty and rarely seen movement. You can even see the bevelage on the whiplash regulator. On the timing machine it shows a maximum variation of 9 seconds between all positions and an amplitude of 280o in the dial up position. A good result for a watch of any age. The basic design for the Chesterfield series of movements was done by George Reed who also did several of the designs for the Rockford Watch Co. Personally I think this watch, the grade 431, ranks up in the top 10 of any 12s movement made. The fit, finish and detail matches or exceeds any watch of similar quality from that era that I have worked on.

Shined up the “Permenant” case that is almost certainly original to the factory cased watch. There is a little brassing just below the stem but it is hardly noticeable. I donated a refinished, but period correct, dial and my favorite “open diamond” hands to complete the watch. To be totally period correct it should have Breguet hands but I don’t particularly like the look of those over the “open diamond.”

This is why I love fixing watches, to get something as nice looking and smooth running as this “Masterpiece”, the South Bend grade “431”. I use all synthetic oils, so if used lightly it will be good for another 30+yrs without any “gumming” up. Of course, if it were to be a regular “carry” watch then it would need to be serviced in about 3-5 years, depending on the general humidity and air quality of the particular environment.

Hope you had as much fun reading the article as I did writing it! If you want more articles drop me a line and let me know what you’re interested in. Always glad to get email that isn’t spam! 😀

Many thanks to Orville Hagans, Jesse Coleman, Paul Berg, O.B. Frye, and Lindell Riddle for sources and information in general about the South Bend Watch Co. Without their work and inspiration this article would not have been written. Special thanks to L.V.Riddle for supplying the watch!

Author: Frank Kusumoto, link to original location: https://web.archive.org/web/20060107064934/https://southbendhorology.com:80/movements/431/index.html